New technologies applied to the improvement of the physical and organoleptic characteristics of the final product

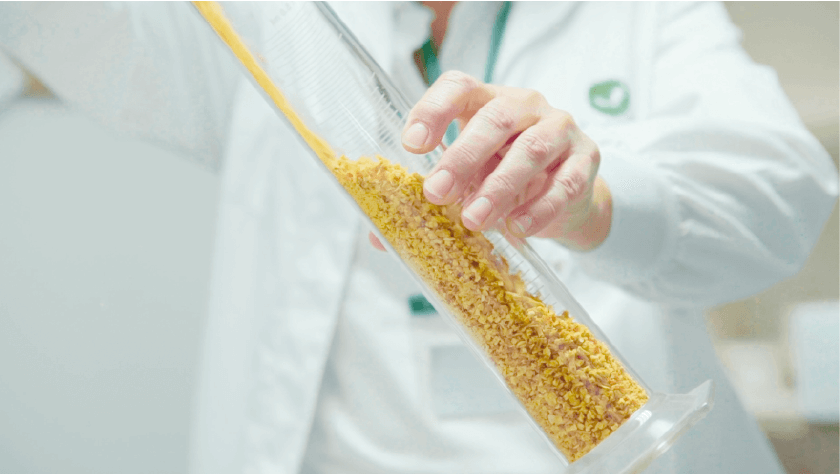

DEHYDRATED

Installed capacity of more than 8,000 liters/hour of evaporated water, supplied by four triple-band drying tunnels and multiple sectors.

This allows and guarantees an exhaustive control of the drying operation, thereby obtaining optimal results in terms of physical and organoleptic characteristics of the final product, as well as internally developed process techniques to achieve excellent microbiological results.

R+D

Knowledge and quality at the service of the satisfaction of our customers.

HIGH MICROBIOLOGICAL QUALITY

Since its inception, Vegenat has been committed to innovation in products and processes throughout its product manufacturing chain, with the aim of supplying high-quality ingredients for the food industry.

Vegenat develops its own crop seeds for dehydration. To do this, it has a Plant Improvement Center in which a team of plant breeders, biotechnologists and field technicians select and improve plant material through direct and applied research programs.

Biotechnology, the application of excellent and respectful agricultural practices from an environmental point of view, as well as a complete monitoring of the crops through our technicians, allow us to obtain raw materials that exceed current requirements and regulations.

These raw materials, after a careful drying process, ensure that products of high microbiological quality are obtained, versatile and with optimal nutritional and organoleptic attributes.